KUREHA Microsphere S series

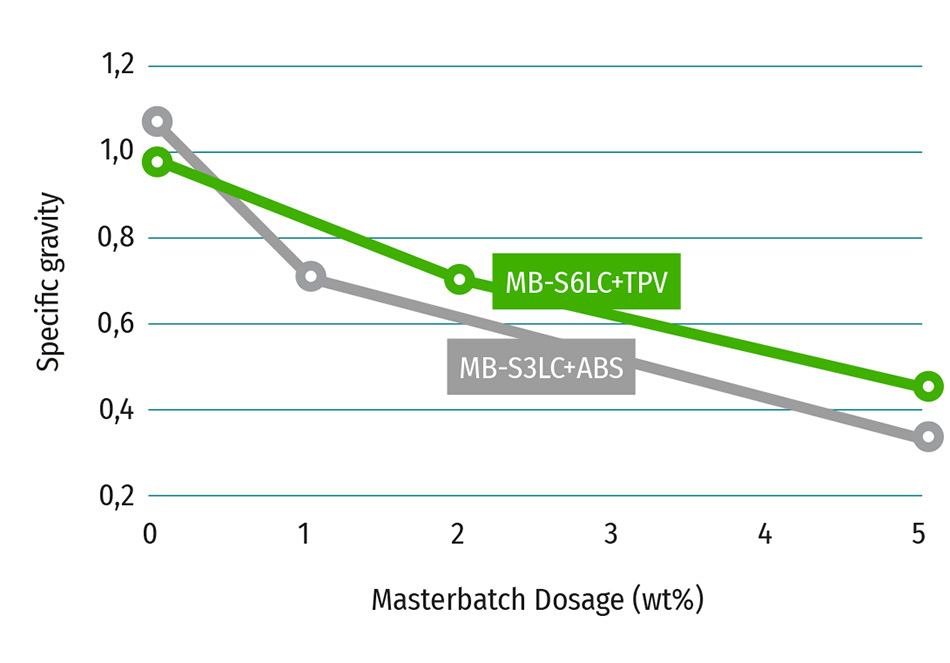

- S series, can be foamed above 190°C and are suitable for foam molding of engineered plastics and elastomers.

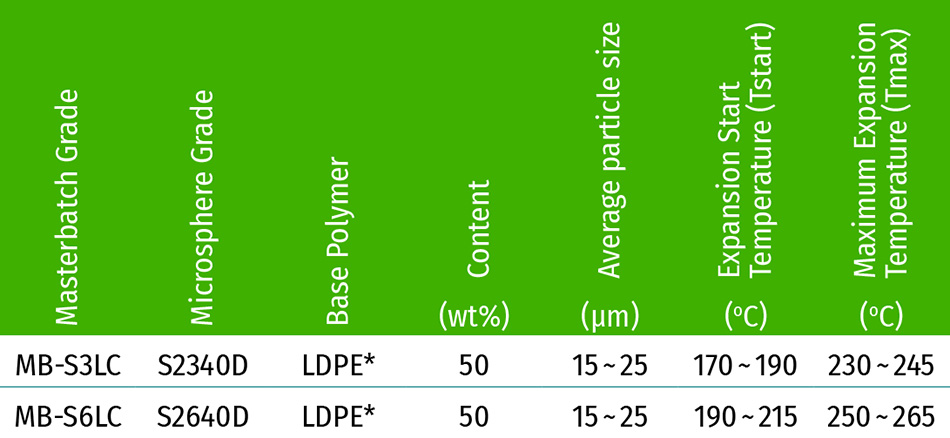

- When molding by blending with pellets, we recommend masterbatch with excellent dispersibility.

- As a guideline for additive amount of masterbatch, we recommend 2 to 3% for weight reduction and 2% or less for sink mark prevention.

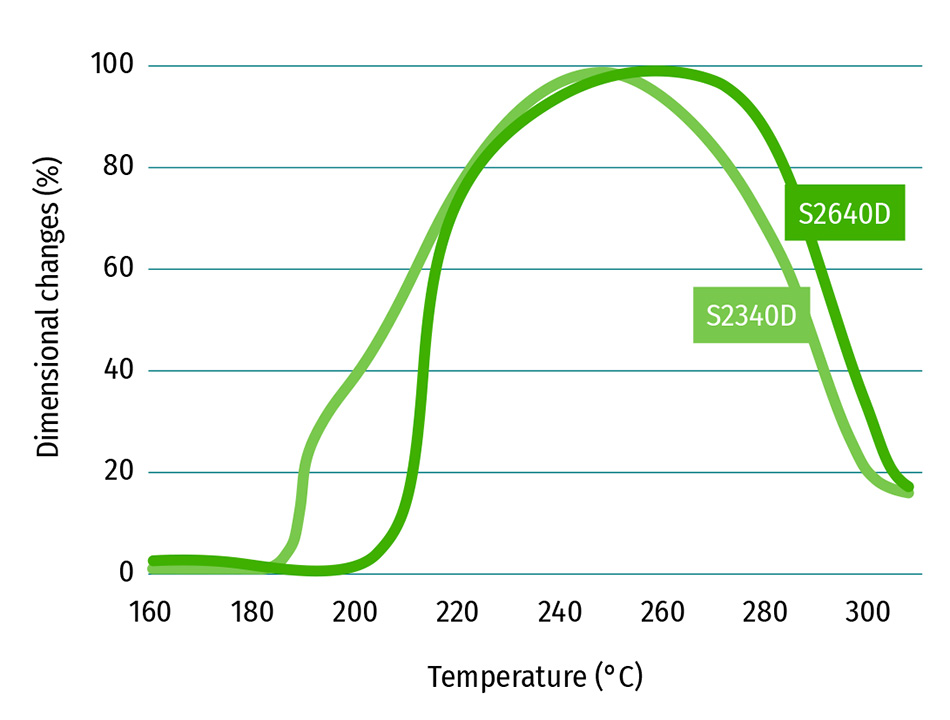

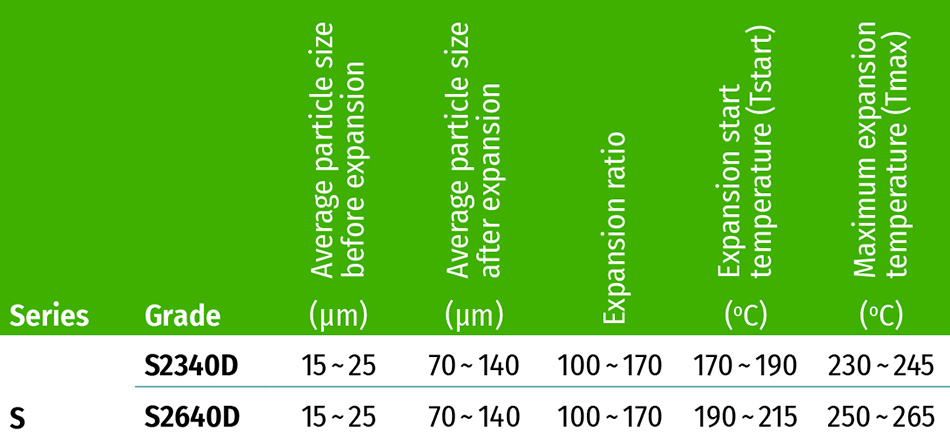

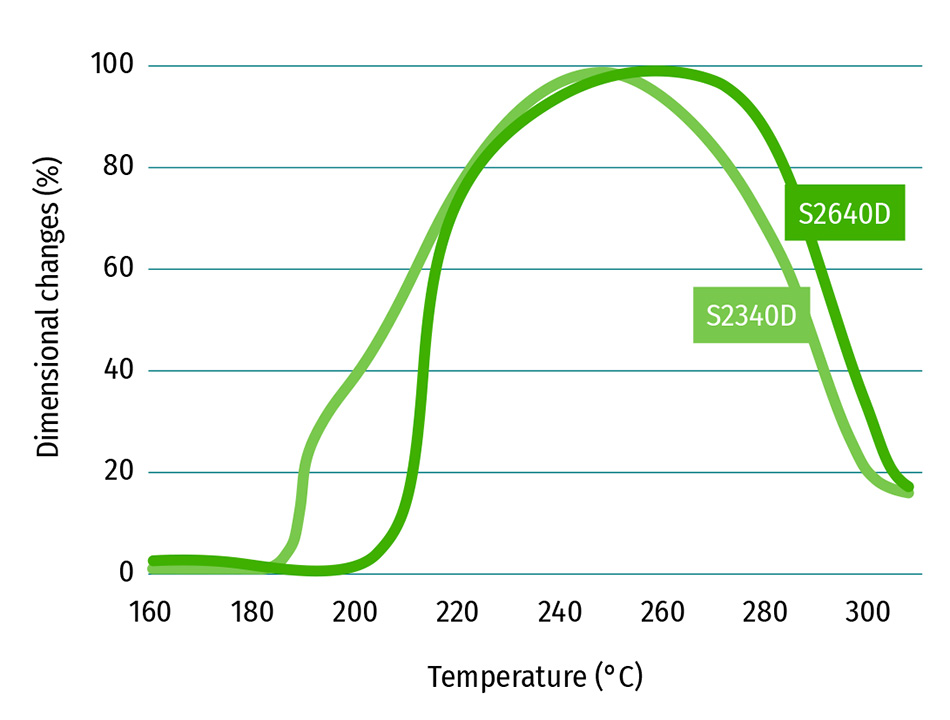

Thermal mechanical analysis: S series

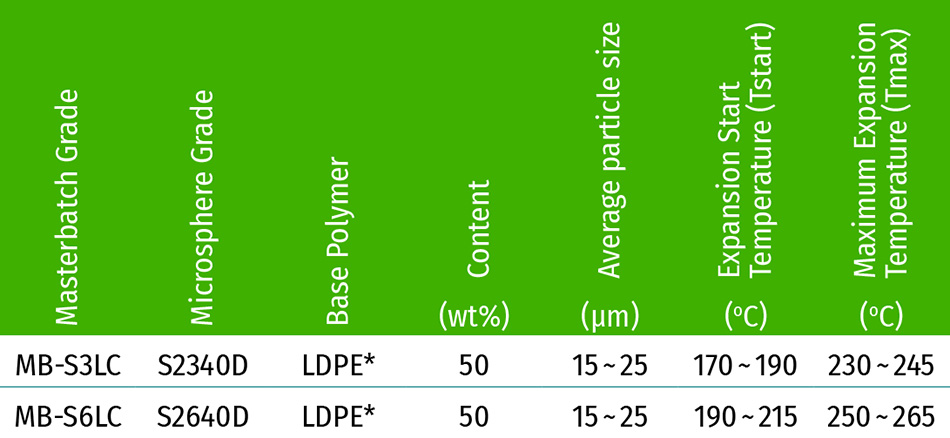

Masterbatch grades

*LDPE: Low density polyethylene

*LDPE: Low density polyethylene

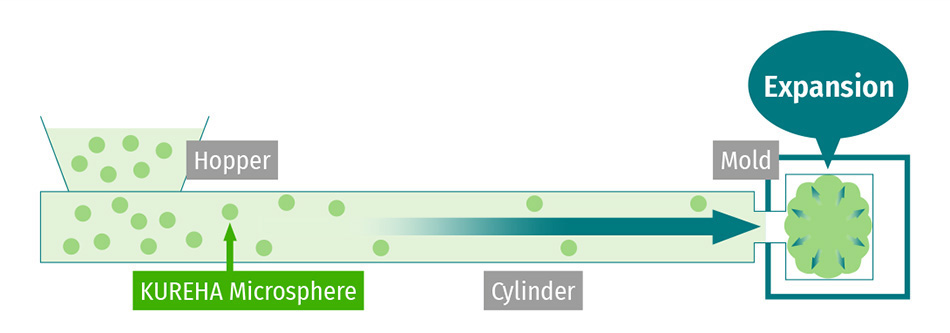

Video: Foam molding

Foam molding used KUREHA Microsphere

Extrusion foam molding

- S2340D: It's suitable for applications with molding temperatures from 190°C to 230°C. Suitable for expansion of engineered plastics such as PP and ABS.

- S2640D: The highest temperature sphere suitable for process temperatures that range from 230°C to 260°C or when avoiding expansion in step-1 of a 2-step molding process.

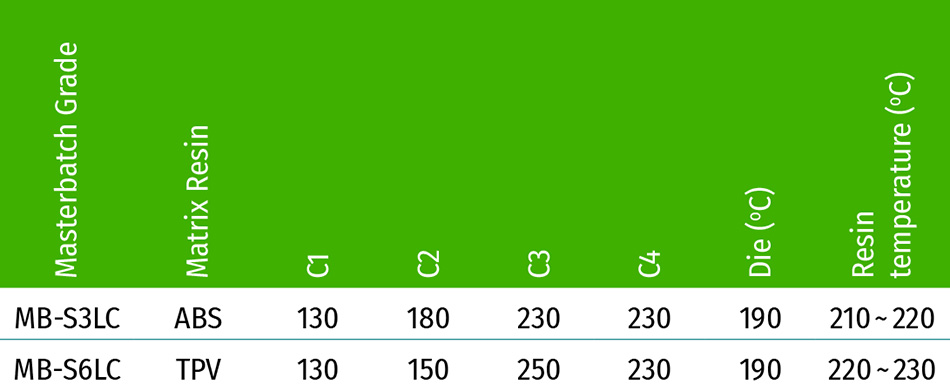

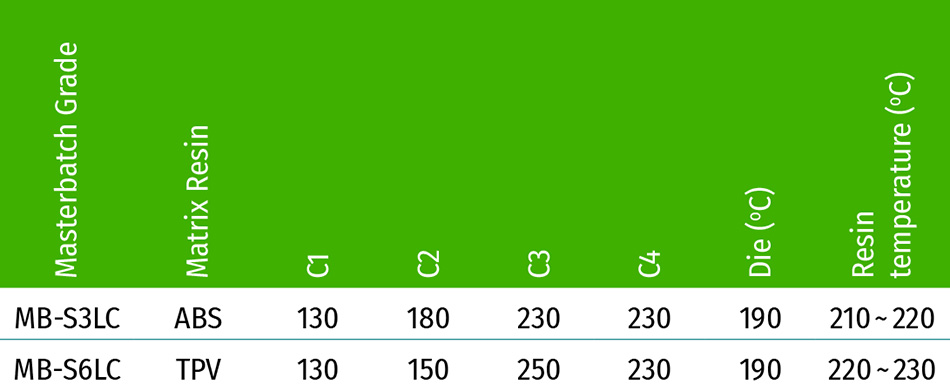

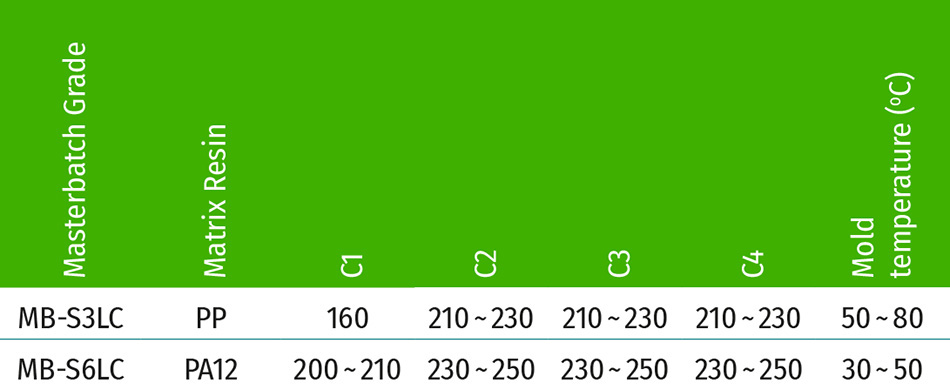

Example of process conditions

C1~C4 : Cylinder temperature (°C)

C1~C4 : Cylinder temperature (°C)

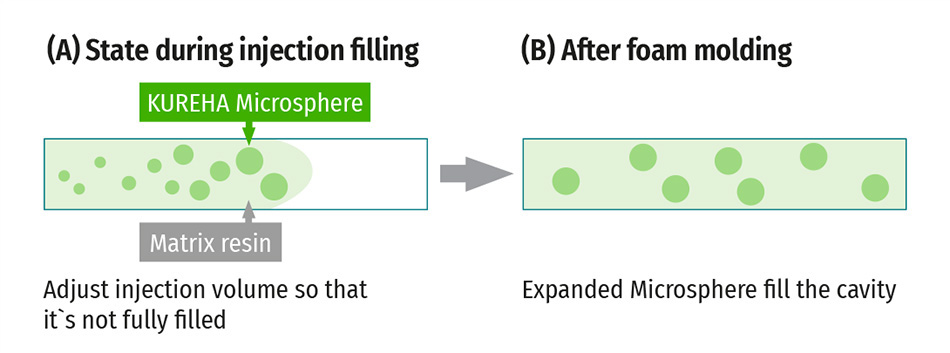

Injection foam molding

- Short shot method used in injection molding.

- Method in which small amount of melt is injected with respect to volume of cavity (Fig. A), and the space is filled by foaming (Fig. B).

- Specific gravity of the product depends on the amount of injected resin.

- KUREHA Microspheres expand when pressure drops (after passing through the nozzle).

- Recommend attachment of shut-off nozzle to prevent from resin dripping.

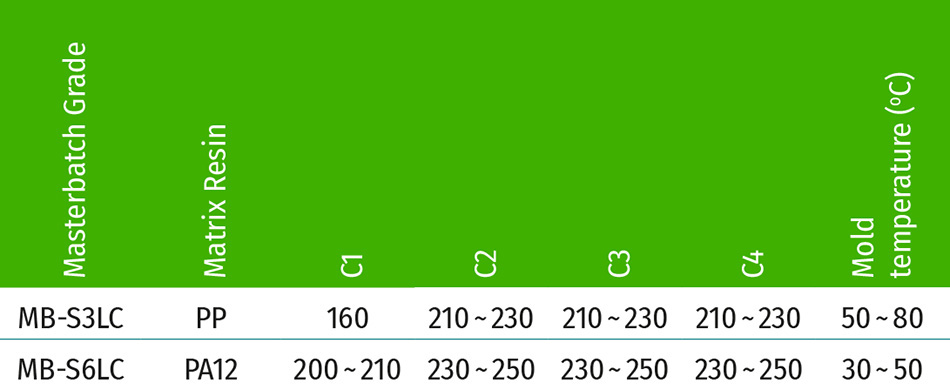

Temperature condition example

C1~C4 : Cylinder temperature (°C)

C1~C4 : Cylinder temperature (°C)

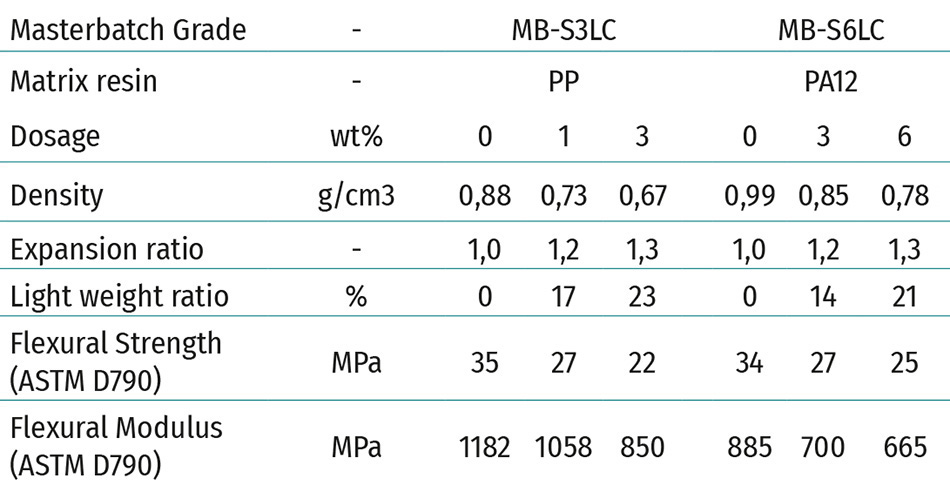

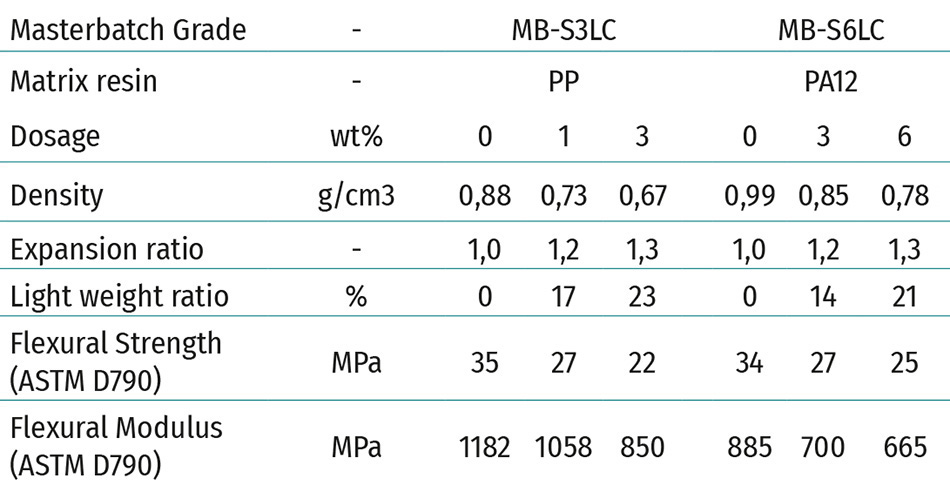

Physical Property

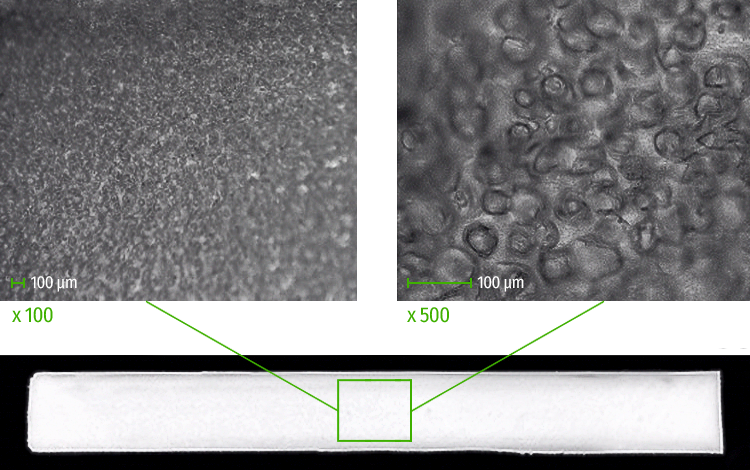

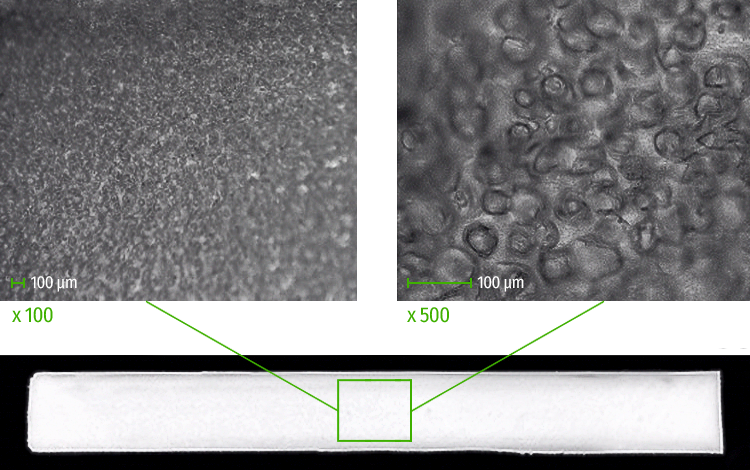

Sectional images of PA12 foams (MB-S6LC: 6 wt%)

Size: 128 mm x 12.8 mm x 12.8 mm / Expansion ratio: 1.3 times / Particle size (Closed cell): 50 ~ 80 μm

Size: 128 mm x 12.8 mm x 12.8 mm / Expansion ratio: 1.3 times / Particle size (Closed cell): 50 ~ 80 μm

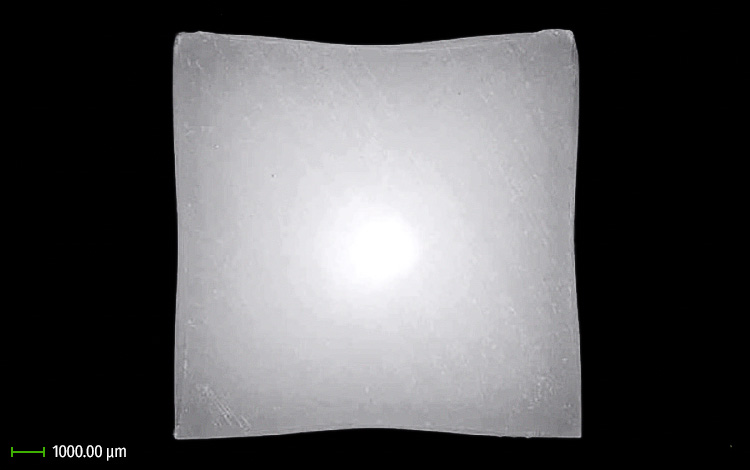

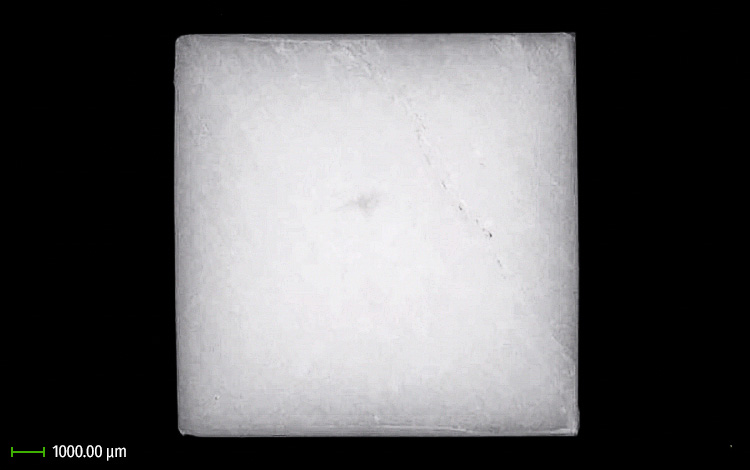

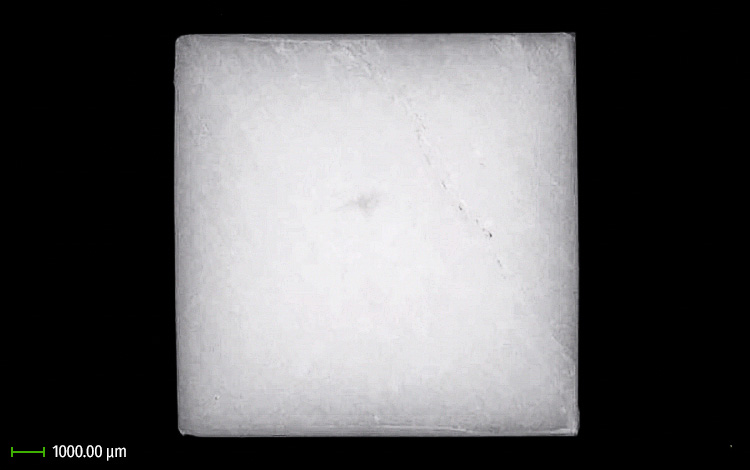

Improved moldability

- The use of KUREHA microspheres improve moldability (prevention of sink marks).

- 2% or less of masterbatched microspheres can improve molding performance.

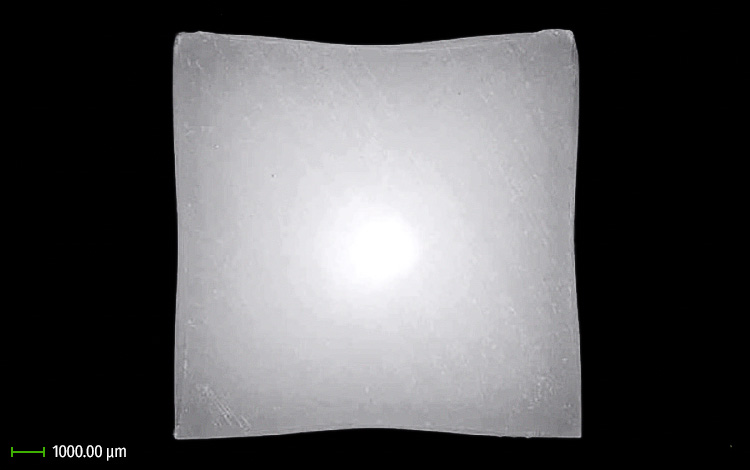

Photo: Molded piece without KUREHA Microsphere

With KUREHA Microsphere

*LDPE: Low density polyethylene

*LDPE: Low density polyethylene

C1~C4 : Cylinder temperature (°C)

C1~C4 : Cylinder temperature (°C)

C1~C4 : Cylinder temperature (°C)

C1~C4 : Cylinder temperature (°C)

Size: 128 mm x 12.8 mm x 12.8 mm / Expansion ratio: 1.3 times / Particle size (Closed cell): 50 ~ 80 μm

Size: 128 mm x 12.8 mm x 12.8 mm / Expansion ratio: 1.3 times / Particle size (Closed cell): 50 ~ 80 μm