Contact

KRECA FR is a high-purity insulation material that is ideal for use in high-temperature furnaces such as for metal heat treatment, ceramic sintering, and silicon ingot pulling.

KRECA FR, which has excellent insulating properties, is a product designed for use in furnaces with a high-temperature closed atmosphere. The graphitized carbon fiber insulation is manufactured by molding carbon fiber felt into specified shapes, such as boards, disks, and cylinders, using a small quantity of binder.

Kureha has a regular stock of standard boards in a warehouse in Germany.

Grade: R202 (graphite foil on both sides)

Bulk density: 0.16 g/cm3

Size:

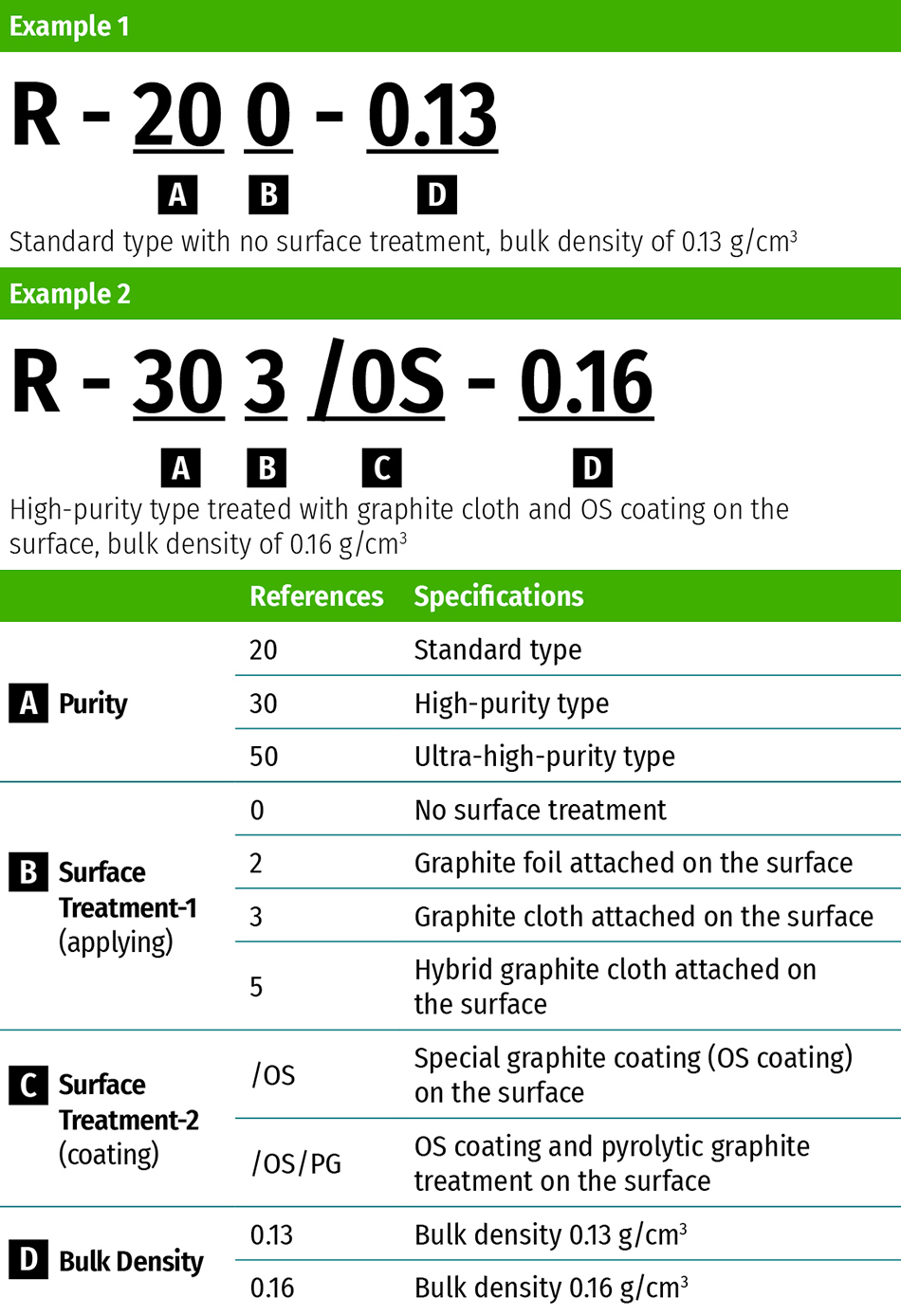

Types and Grades

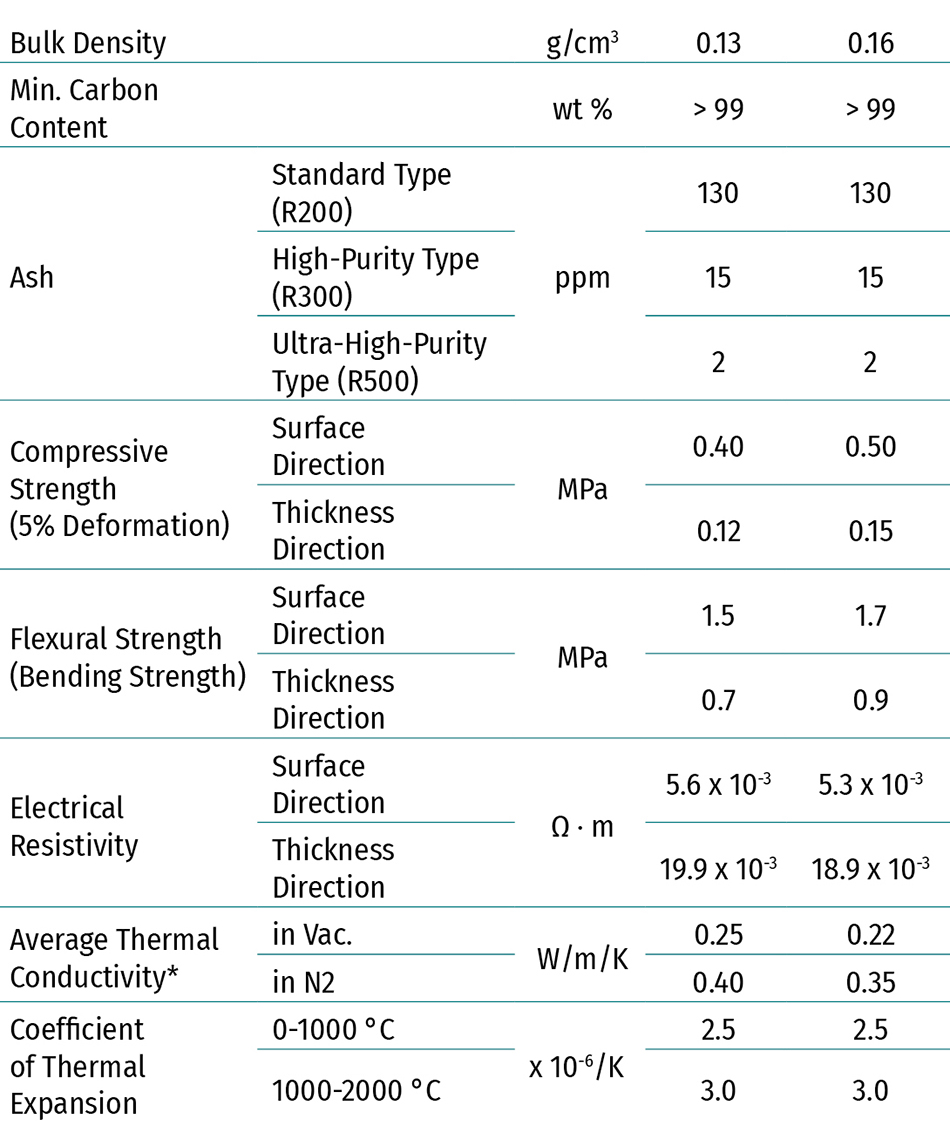

Typical physical properties and characteristics

Measuring method: Kureha standard test method.

*At 1,500 degrees Celsius, test pieces with 50 mm thickness

Measuring method: Kureha standard test method.

*At 1,500 degrees Celsius, test pieces with 50 mm thickness

Average thermal conductivity (in vac.)

Under an atmosphere of 1.33Pa, 50 mm thick test pieces

Under an atmosphere of 1.33Pa, 50 mm thick test pieces

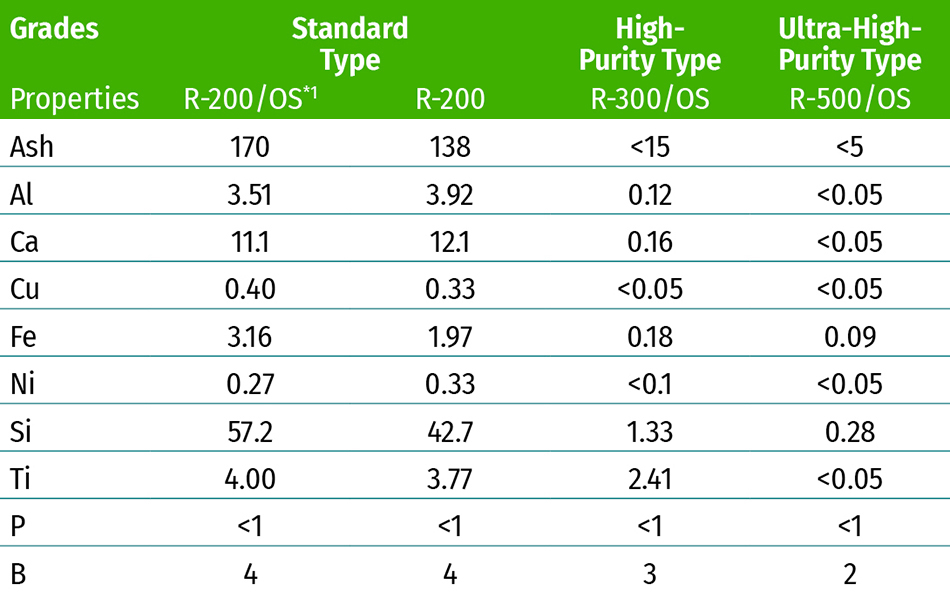

Impurities contained

1 Assay of OS coating in R-200/0S weigh around 10% of the insulation itself in average.

Ash content of "High-purity type" and "Ultra-high purity" will not be effected by the surface treatment. / Unit: ppm

1 Assay of OS coating in R-200/0S weigh around 10% of the insulation itself in average.

Ash content of "High-purity type" and "Ultra-high purity" will not be effected by the surface treatment. / Unit: ppm

Difference in oxidation between types of carbon fiber

Temperatur range: from RT to 1,000 degrees Celsius (10 deg C/min) in air (200L/min)

Temperatur range: from RT to 1,000 degrees Celsius (10 deg C/min) in air (200L/min)

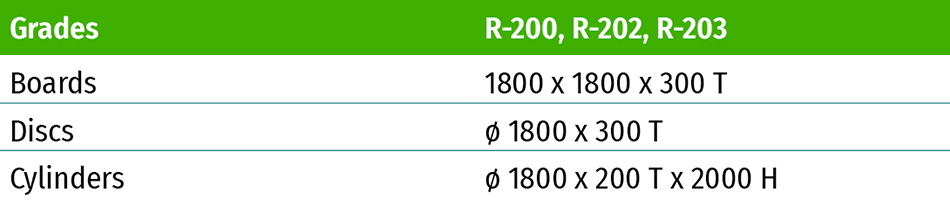

Maximum sizes available

Maximum available sizes differ depending on thicknesses.

Please feel free to contact us about details.

Maximum available sizes differ depending on thicknesses.

Please feel free to contact us about details.